Savoir comment protéger par mot de passe un disque dur externe est essentiel pour votre sécurité numérique globale. ✓ Découvrez comment protéger les PC et les Mac.

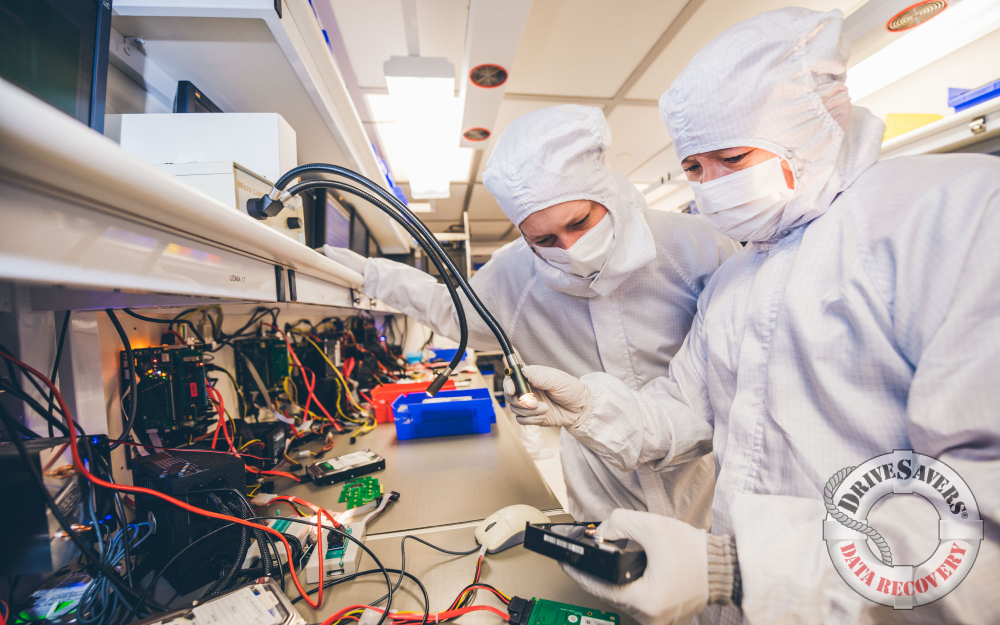

Cleanroom Data Recovery vs. Clean Benches: A Scientific Perspective

When it comes to recovering data from physically damaged hard drives, few details spark more debate than the environment where the recovery takes place. For years, DriveSavers has emphasized its cleanroom data recovery capabilities as a technical differentiator. But is a clean bench — a smaller, less expensive controlled environment — sufficient? Read on to learn howDriveSavers Data Recovery’s investment in a full ISO-certified cleanroom is backed by science.

Let’s break this down with a scientific lens.

What Is a Cleanroom, and How Is It Different from a Clean Bench?

Un frais de salle blanche is an enclosed, engineered space where airborne particles, humidity, and temperature are tightly controlled. Cleanrooms are rated by standards like ISO 14644-1, which define the allowable number of particles per cubic meter. DriveSavers, for example, operates at ISO Class 5, allowing fewer than 3,520 particles (0.5 μm or larger) per cubic meter.

Un clean bench, on the other hand, is a localized area that uses laminar airflow and HEPA filtration to provide a particle-free work surface. While clean benches can be quite effective for certain applications — like electronics assembly or some lab work — they differ fundamentally in scope:

Why Do These Environmental Controls Matter in Data Recovery?

At the heart of clean room récupération du disque dur is the need to protect sensitive internal components of hard drive storage devices — platters, heads, actuators — from contaminants. Even microscopic dust particles can cause accidents de la tête, reducing chances of a successful recovery.

A common analogy is comparing a single dust particle on a platter to a racecar travelling at full speed hitting a boulder. The tolerances are that tight.

While clean benches offer protection on the surface level, they do not eliminate contamination introduced by surrounding air, technician movement, or electrostatic discharge. The cleanroom data recovery protocols used by DriveSavers address all of these risks systematically.

Is a Clean Bench Enough?

It’s true that many successful recoveries can be done on a clean bench. In cases where drive platters are largely intact and the mechanical damage is minimal, the contamination risk may be low enough for bench-level containment to suffice.

However, the main problem with clean benches is the distribution of risk across different case types. DriveSavers sees the full range: fire-damaged drives, flood-immersed systems, failed decryption firmware, degraded magnetic media — situations where even a single contaminant could reduce the odds of recovery from slim to zero.

In those edge cases — the ones where clients may have just one shot — the argument shifts from “what’s good enough?” to “what provides the best odds?”

Cleanroom Data Recovery as Risk Mitigation

For DriveSavers, a certified data recovery clean room is about maximizing recovery rates and minimizing the introduction of any secondary damage. The data on these drives isn’t just digital information — it’s intellectual property, legal evidence, financial records, or years of family photos.

With so much on the line, DriveSavers has made the decision to operate under the most stringent environmental conditions available in the industry — even if 90% of recoveries might be possible with less.

That’s a calculated choice to reduce the remaining 10% risk — and for many clients, that 10% makes all the difference.

Clean Bench Recovery in the Real World

For some professional data recovery shops, especially those focusing on low-cost or consumer-tier drives, clean benches can be a smart choice. They’re lower in cost, easier to maintain, and sufficient for many scenarios.

DriveSavers Data Recovery’s cleanroom is part of a broader commitment to total risk control — not just the workstation, but everything surrounding it.

So, Why Cleanroom Data Recovery?

For some jobs, a clean bench may be fine. However, all data recovery jobs are not created equal.DriveSavers chooses to operate in a cleanroom because it gives our engineers the best chance to recover the data.

An ISO Class 5 Certified Cleanroom provides risk management with a scientific foundation.

Final Thoughts:

Expertise, Not Equipment, Wins the Day

Expertise, Not Equipment, Wins the Day

Alors que la cleanroom data recovery facility at the DriveSavers lab is a differentiator, it’s not a replacement for engineering talent, reverse-engineering tools, or proprietary firmware techniques. It’s a platform — one that helps those other skills work more effectively.

A clean bench in skilled hands can outperform a cleanroom in unskilled hands. But when you combine world-class engineers avec an ISO-certified cleanroom, you create the highest possible odds of success and data protection.

That’s what DriveSavers offers. Not just a place to open a hard drive — but an environment built for the data on it to survive.